Ultimate Rotary Engine Cooling Upgrade: PWR Radiator Boosts Performance

- Authors

- Published on

- Published on

- Name

- By Dushyant

- (@dishs)

In this thrilling episode from the Rob Dahm channel, the team dives headfirst into the heart of a rotary engine cooling dilemma. With dreams of 1,000 horsepower dancing in their heads, they bid farewell to their trusty Bell intercoolers radiator, finding it lacking in the face of such monstrous heat output. Enter PWR, the saviors from the Indie Car project, with a radiator so magnificent it could make a grown man weep. This dual pass beauty promises a 30% boost in heat transfer efficiency, leaving competitors in the dust.

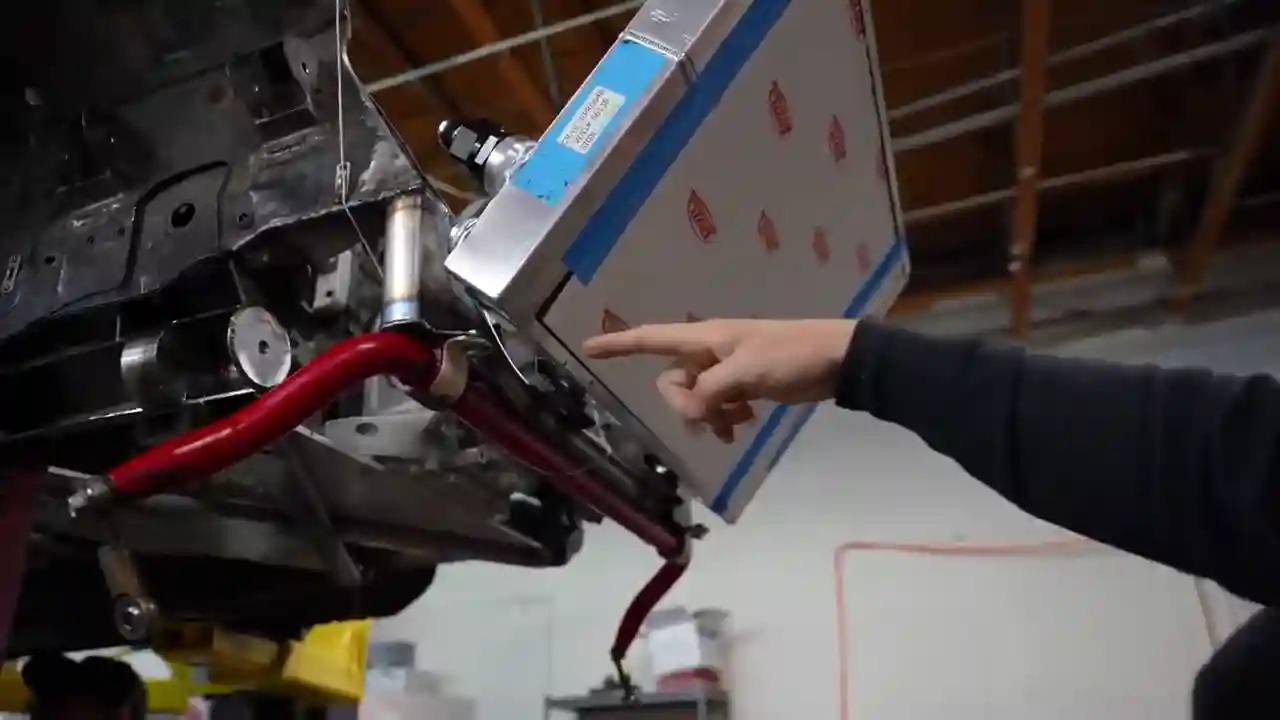

As the team embarks on a quest to revamp the front of their vehicle, challenges abound. The struggle to find space for intercooler piping amidst a sea of side coolers is real. But fear not, for a structural duct system is in the works, promising to revolutionize airflow and cooling efficiency. The stage is set for a showdown between the new oil coolers and the old guard, with the former boasting double the cooling capacity. It's a battle of epic proportions, with turbulators adding a touch of finesse to the heat exchange game.

Amidst the chaos and welding sparks, a stroke of genius strikes the team as they integrate the duct system into the very structure of the car. This innovative approach not only promises enhanced cooling but also adds a layer of crash protection. The team's determination to conquer the cooling conundrum is palpable, with every bend of the tube and weld of the metal bringing them one step closer to rotary engine nirvana. Stay tuned as the team races against time to unleash the full potential of their beastly machine, pushing the boundaries of engineering and performance in the pursuit of rotary perfection.

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Watch The COOLEST RX-7 ever. I’m done overheating on Youtube

Viewer Reactions for The COOLEST RX-7 ever. I’m done overheating

Viewers are impressed with the frequency of build videos being released

Positive comments about the educational content and explanations provided in the video

Appreciation for the attention to detail and craftsmanship in the build

Excitement for the progress and development of the project

Comments on the unique and high-quality nature of Rob Dahm's RX7 builds

Suggestions for potential modifications or improvements to the vehicles

Interest in the Diablo and its condition

Questions about specific technical aspects of the build

Comparisons to other YouTube channels or builders

Expressions of anticipation for future updates and racing potential, such as Pikes Peak

Related Articles

Rob Dahm: Shiny 3D Scanner, Clutch Kit, and 3D Printed Car Ducts

Rob Dahm showcases the Shiny 3D scanner's advanced capabilities, discusses a new clutch kit, and introduces Eight Sleep's innovative technology. The team delves into 3D printing ducts for the car, highlighting challenges and successes in the process.

Rob Dahm's Team Revs Up Three-Rotor Engine for Pikes Peak Success

Rob Dahm's team prepares the three-rotor engine for Pikes Peak, overcoming challenges like rotor damage and seal issues. With meticulous rebuilding and innovative techniques, they enhance performance for the upcoming race.

Building the Lightest Mazda Rotary Engine: Precision and Billet Components

Rob Dahm's team works on creating the lightest Mazda-based rotary engine ever, focusing on billet components and precision assembly for optimal performance.

Reviving an Iconic Indie Car: Unveiling the Transmission Casing

Rob Dahm revives an iconic Indie Car, unveiling its versatile transmission casing. Discover the car's history, intricate mechanics, and the team's journey to restore it to its former racing glory.