Transforming a $300 Nissan 300ZX: Downpipe, Exhaust, and Intercooler Upgrades

- Authors

- Published on

- Published on

- Name

- By Dushyant

- (@dishs)

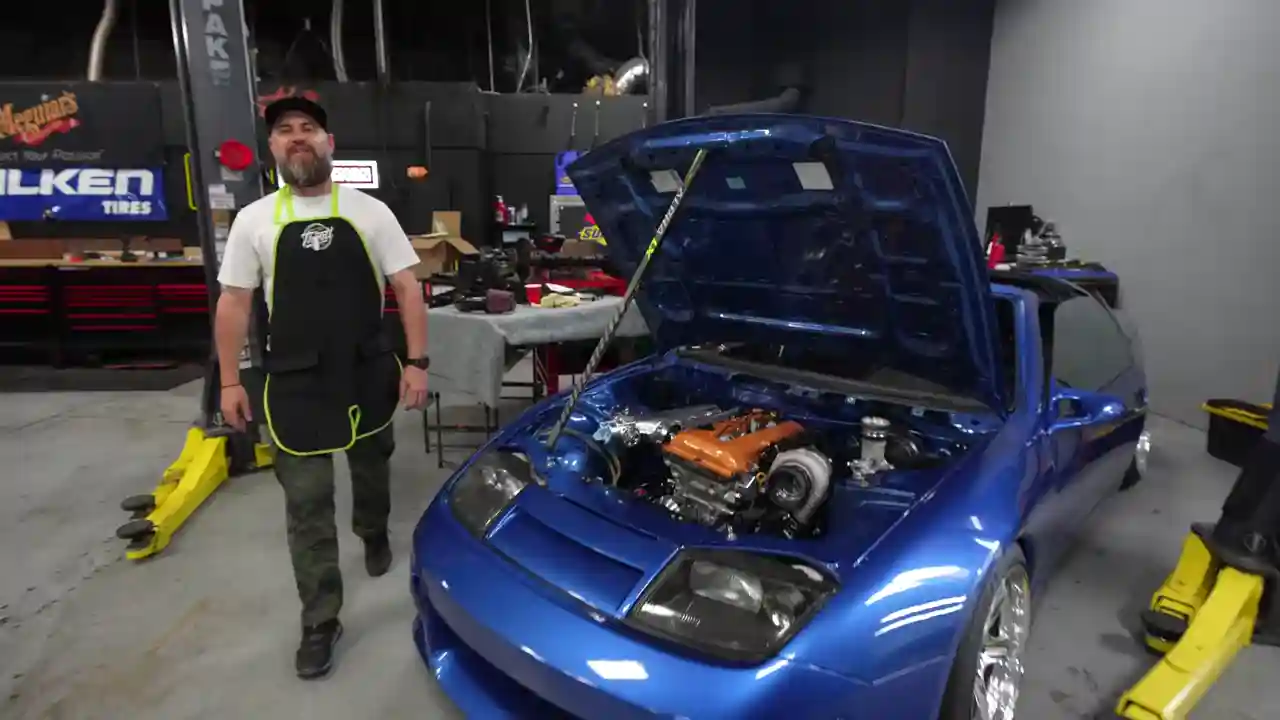

In this episode of throtl, the team takes on a $300 Nissan 300ZX with an SR20 swap, just a stone's throw away from its first start. The first order of business is the downpipe, a crucial link between the turbo and exhaust system. With meticulous fabrication work, including the addition of a bellows for flexibility, they ensure a secure connection. Vibrant pie cuts come into play for the exhaust, allowing for a precise fit above the frame rails and a sleek axle-back section.

Moving on to the wastegate dump tube, the team meticulously crafts it to ensure optimal performance. They pay close attention to details like the length and angle of the muffler tip, adding a touch of flair to the build. Creating custom hangers for the exhaust system becomes a hands-on task, requiring careful welding and placement to ensure stability. With the exhaust system taking shape, the focus shifts to the intercooler piping, where vibrant aluminum pipes and a blowoff valve are utilized for maximum efficiency.

As the SR20 engine is primed and oil flow confirmed, tuning expert Sean Christensen steps in to load the base map and fine-tune the setup. A meticulous check of the timing is carried out using a timing light, ensuring everything is in sync for the first start. With anticipation building, the team prepares to crank the engine, only to face a hiccup that prompts a compression check before attempting to ignite the beast.

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Watch Starting our SR20DET Swapped Nissan 300ZX for the FIRST TIME EVER!!! (Did not go as planned) on Youtube

Viewer Reactions for Starting our SR20DET Swapped Nissan 300ZX for the FIRST TIME EVER!!! (Did not go as planned)

Welding safety tips and recommendations

Appreciation for the build progress and skills shown

Positive feedback on the project and team's work

Suggestions for improvement in welding techniques

Comments on the sound of the car

Requests for more rotary content

Concerns about health risks related to welding

Praise for the team's communication and improvisation skills

Questions about specific aspects of the build, like back purging with argon

Compliments on the engine sound and overall project success

Related Articles

Mustang Mach 1 Transformation: Vortex Supercharger & Magnaflow Exhaust Upgrade

Throttle Dream Build 10 transforms a worn-out Mustang Mach 1 with upgrades like a Vortex supercharger, Magnaflow exhaust, and fresh paint, showcasing expert engine and suspension work. The team's meticulous attention to detail results in a show-stopping masterpiece.

Throttle Drag Racing Showdown: High-Performance Cars and Intense Competition

Throttle's drag racing event at Verona Speedway showcased high-performance cars like Quinn's supercharged Mustang and Anthony's F80M3 with a Vargas Turbo single turbo conversion. The intense races, negotiations, and unexpected outcomes made for a thrilling competition.

Abandoned Mercedes Rebuild: Custom Exhaust, Widebody Kit & 418 HP Dyno Run

Witness the epic transformation of an abandoned Mercedes with a 5.2 L Ford Voodoo crate engine. From a custom Magnaflow exhaust to a widebody kit and forged HRE wheels, this rebuild is a true showstopper. Feel the power of 418 wheel horsepower on the dyno and experience the thrill of smoky burnouts in this impressive rebuild journey by throtl.

Reviving Fast and Furious: Acura Integra Transformation with Authentic Parts

throtl transforms a legendary Acura Integra from the Fast and Furious movie with authentic parts. Expertly upgrading exhaust, brakes, suspension, body kit, and wheels for a movie-accurate masterpiece. Join the journey with Shahar, a Fast and Furious replica car builder, as they bring this iconic car back to life.