The Truth About Aftermarket Brake Pads: Are They Playing by the Same Rules?

- Authors

- Published on

- Published on

- Name

- By Dushyant

- (@dishs)

In this video, Engineering Explained delves into the fascinating world of aftermarket brake pads. They've got five different brake pads from reputable companies, but here's the twist: some of these aftermarket guys are making questionable decisions that the average consumer would never even notice! It's time to peel back the curtain, or in this case, the friction material, and expose the truth. You see, there are four key elements to brake pad design that are crucial for functionality and safety. And today, we're focusing on just one: the attachment of the friction material to the backing plate.

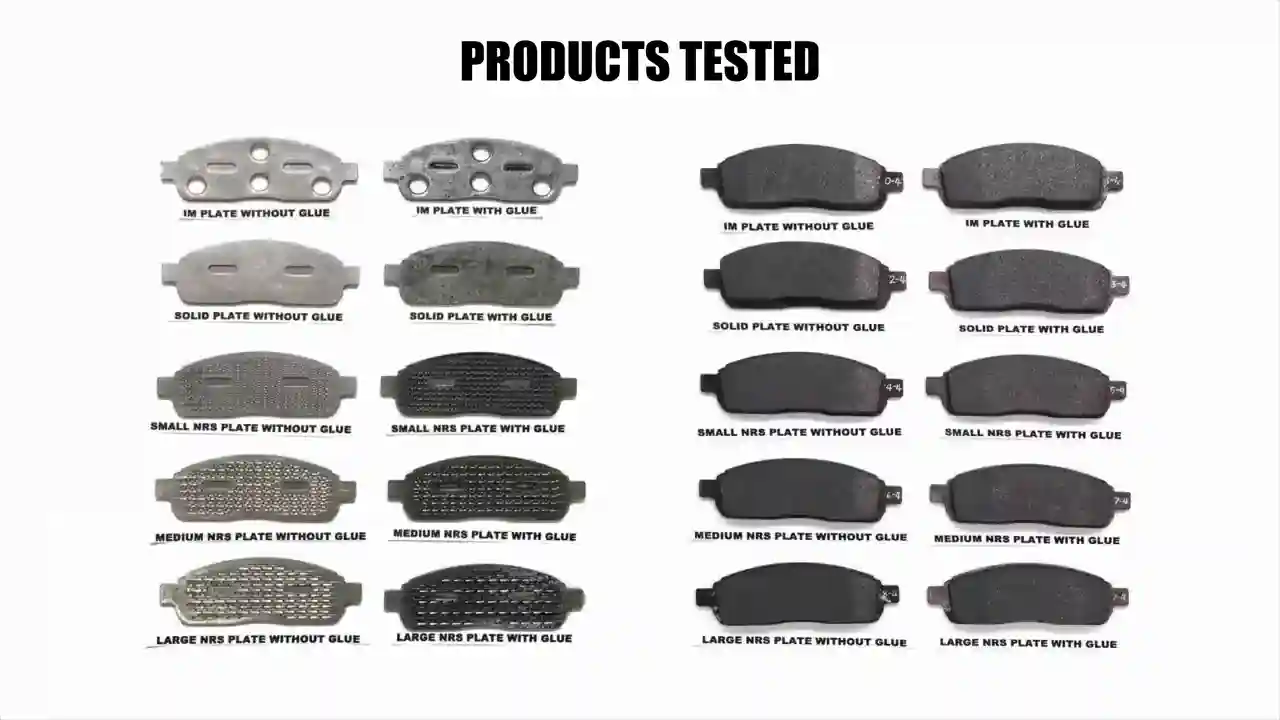

Now, let's get up close and personal with these brake pads. We've got the original equipment pad, the NRS pad, and three other aftermarket options. The original equipment pad uses a mechanical attachment, and you can see it with these little metallic reflections. It's clear as day. But here's the kicker: you can buy brake pads for the same vehicle without this mechanical attachment. It's like a hidden secret, and the average Joe would never know!

But hold on, we need to rewind a bit and understand how we got here. Back in the day, all brake pads had this old-school mechanical attachment with rivets. Sure, it had its advantages, but it also meant you had all these holes in your brake pad, which wasn't ideal. Then came the adhesives, the game-changer. The industry developed adhesives that could bond the friction material to the backing plate, and it worked like a charm. No more holes, no more worries. But here's the thing: not everyone jumped on the adhesive bandwagon.

In heavy-duty truck works and even track-oriented sports cars, manufacturers still swear by mechanical attachments. And that's exactly what we have here with these five brake pads. They're all for one of the most popular heavy-duty pickup trucks in America. You could easily buy any of these sets for your truck, but be warned, not all of them have that mechanical attachment. The original equipment pads, as expected, have it. And NRS, well, they're all about mechanical attachments. But there's this one aftermarket pad that's got us scratching our heads. It's aftermarket, yet it features a mechanical attachment. Now, that's interesting!

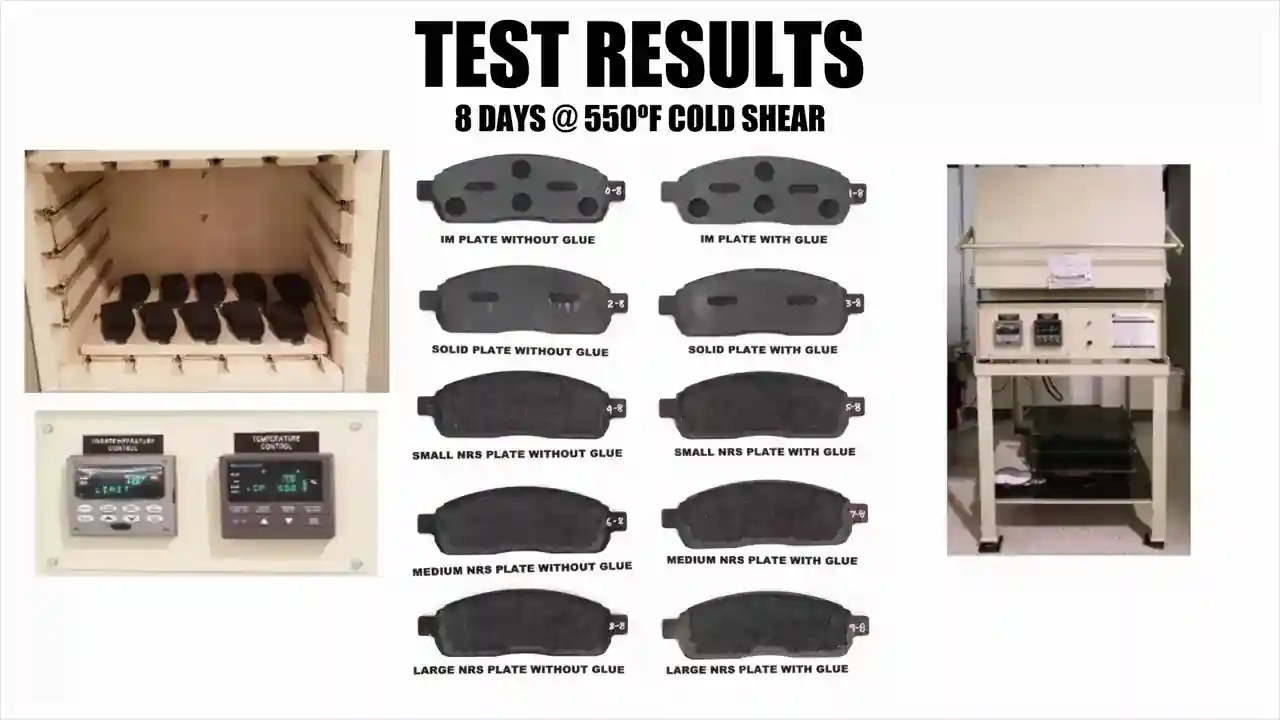

So, the big question is, what should be done about these aftermarket companies that aren't playing by the same rules as the original equipment suppliers? It's a dilemma, my friends, and one that needs some serious attention. The world of aftermarket brake pads is a wild one, filled with hidden secrets and questionable decisions.

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Watch The Sketchy Truth About Aftermarket Brake Pads on Youtube

Viewer Reactions for The Sketchy Truth About Aftermarket Brake Pads

Data changes by suppliers causing fitment issues

Performance difference between OEM and off-brand pads

Personal experiences with mechanical attachment and adhesive failure

Questions about the cutaway pads provided by NRS

Request for more information on other differences between brake pads

Suggestions for conducting real-world testing

Concerns about the validity of the test shown in the video

Personal experiences with brake pad failures and upgrades

Preference for OEM pads and DIY brake maintenance

Instances of pad failure and the importance of using quality pads

Comments about the temperature and performance of glued pads

Personal experiences with aftermarket pads and the importance of OE parts

Questions about the durability and quality of certain brake pad brands

Request for a video exposing specific brands of brake pads

Comments about the importance of safety and using OE parts

Personal experiences with brake pad failure and the impact on driving

Recommendations to buy premium brake pads from reputable brands

Comments about the lack of oversight in the industry

Examples of brake pad failures in amusement park rides

Speculation about the motivation behind the video

Comments about the unscientific methods used in the video

Related Articles

Unveiling Corvette ZR1: Acceleration Secrets and Track Dominance

Engineering Explained reveals the Corvette ZR1's astonishing acceleration, custom launch control secrets, hidden red line, and exceptional handling capabilities, showcasing its dominance on the track.

GM Engine Failures: Thicker Oil Solution Revealed

Engineering Explained uncovers GM's engine failures due to manufacturing defects, recommending a switch to thicker oil for optimal engine performance and longevity.

Exclusive Review: Cadillac Celesteic Unveiled - Luxury & Innovation

Experience the Cadillac Celesteic: a $350,000 flagship sedan with 655 hp, 303 mi range, and unique manufacturing techniques like massive aluminum castings and 3D printed metal parts. Discover the luxury of low-volume production and innovative design in this exclusive review.

Revolutionizing Downforce: McMerry Spearling's Impact on Racing

The McMerry Spearling revolutionizes downforce creation with fan technology, showcasing remarkable efficiency and potential for Formula E and Formula 1.