StanceWorks: Overcoming Challenges in Fitting K20 Engine & Turbo Upgrade

- Authors

- Published on

- Published on

- Name

- By Dushyant

- (@dishs)

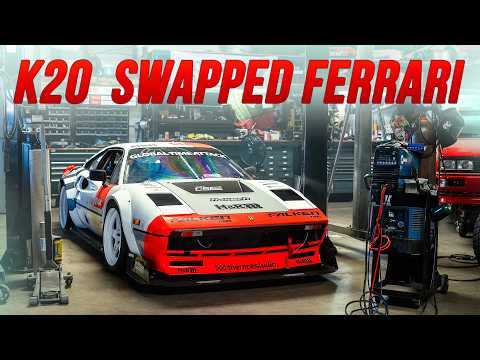

In this thrilling episode from StanceWorks, the team faces a race against time as they tackle the daunting task of fitting a K20 engine into their car, presenting unexpected challenges at every turn. With the cylinder head change causing a cascade of adjustments needed throughout the vehicle, the team finds themselves in a high-stakes situation where every modification must be executed flawlessly to meet their impending deadline. The pressure is on as they strive to reconfigure components like the intake manifold and exhaust pipes to accommodate the new engine setup, all while keeping their eyes on the prize of getting the car ready for the upcoming track event.

Amidst the chaos, the team dives into the intricacies of installing a new turbocharger, leading to a complete revamp of the exhaust system. From realigning the wastegate dump tube to fabricating a brand-new exhaust pipe, the crew encounters a series of hurdles that demand their expertise and precision. Collaborating with a skilled machinist, they embark on a journey to customize a stainless steel transition, showcasing their dedication to achieving perfection in every detail of the exhaust layout. Despite setbacks and meticulous adjustments, the team remains unwavering in their pursuit of excellence, ensuring that every angle and connection in the exhaust system is meticulously refined to meet their exacting standards.

As the project nears completion, the team's attention turns to aligning the wastegate dump pipe and ensuring uniform angles throughout the exhaust system. Through a process of iterative modifications and precise welding, they meticulously tailor the exhaust tips to uniform lengths, adding the final touches to their masterpiece. However, challenges persist as they encounter difficulties in sourcing suitable parts for the charge pipe, forcing them to navigate through setbacks like illness while maintaining their unwavering commitment to completing the project on time. With sheer determination and a relentless pursuit of perfection, the team pushes forward, ready to conquer the track and showcase their creation at the upcoming racing event.

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Watch My Ferrari goes from K24 to K20, and it's more work than I expected. on Youtube

Viewer Reactions for My Ferrari goes from K24 to K20, and it's more work than I expected.

Carly's scanner and free version of the app with standard OBD features are compatible with cars that have an OBD2 port

Focus on small aesthetic details in the video

Acceptance of imperfections in the video editing process

Appreciation for the immersive and less polished format of the video

Use of finger as a unit of measure for checking gaps between parts

Praise for craftsmanship and attention to detail

Request for lapel mic setting adjustment for better audio experience

Desire for bozosuku style exhaust

Positive feedback on the host's welding skills

Appreciation for the real-time and engaging content provided

Related Articles

Building Custom Engine Run Stand for Ferrari F-140GA V12

StanceWorks builds a custom engine run stand for the powerful F-140GA V12 from a Ferrari 812 Superfast. Precision welding, quality materials, and collaboration with Send Cut Send ensure a durable and functional design.

Exploring CNC Machining with Carva: Precision Part Production Journey

StanceWorks introduces CNC machining with the Carva desktop machine, showcasing its features and capabilities. Follow their journey into precision part production and the excitement of creating custom components for their projects.

StanceWorks F40 Project: A-Pillar Crafting and Windshield 3D Scan

StanceWorks F40 project ramps up with technical details and body alignment focus. A-pillars crafted, fiberglass placeholders installed, and 3D scan planned for Lexan windshield replication. Support the project through subscriptions, merchandise, or Patreon.

StanceWorks Transforms E36 M3 and 328 with Custom Wheels and Enzitech Wrap

StanceWorks transforms neglected E36 M3 and E36 328 into stunning rides with custom AC Schnitzer and BBS LMS wheels. Full wrap in Enzitech's midnight purple elevates the E36's aesthetics. Experience the meticulous craftsmanship and passion of the team.