Recreating $23,000 Lamborghini Mercil Headlights: A DIY Journey

- Authors

- Published on

- Published on

- Name

- By Dushyant

- (@dishs)

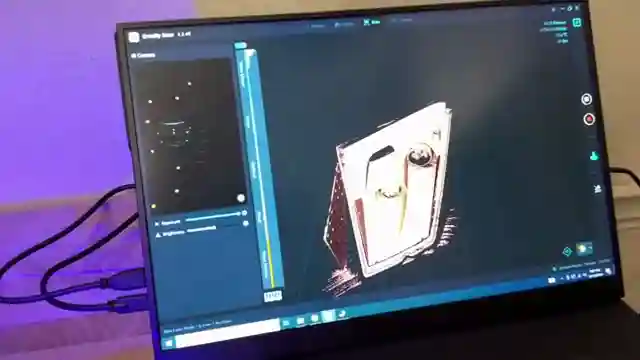

In this riveting episode of B is for Build, the team embarks on a daring mission to recreate Lamborghini Mercil logo headlights worth a staggering $23,000. With only a cracked lens to work with, they dive headfirst into the intricate process of 3D scanning the headlight and meticulously designing a replacement. Utilizing cutting-edge technology from Creality, they scan the headlight housing with unprecedented precision, paving the way for a flawless recreation.

The adrenaline-fueled journey continues as they fire up the resin printer to craft the intricate headlight bezels, a crucial component in the reconstruction process. With meticulous attention to detail, they assemble the tubes and housings, painstakingly sanding and painting each piece to perfection. The addition of LED lighting injects a touch of modern flair, setting the stage for the grand finale - mounting the headlights into the car with precision and finesse.

As the project nears completion, the team faces a final challenge - constructing lenses for the headlights that mirror the original design. With expert craftsmanship and unwavering determination, they meticulously build the lenses, ensuring a seamless fit onto the headlight housing. Through ingenuity and sheer grit, they secure the headlights into the car using innovative nutserts, a testament to their unwavering dedication to perfection in every detail.

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Watch I SAVED $23,000 By 3d Printing My Own Lamborghini Murcielago Headlights on Youtube

Viewer Reactions for I SAVED $23,000 By 3d Printing My Own Lamborghini Murcielago Headlights

Viewers are impressed with the homemade headlights and the use of new technology in the build

Suggestions for improving 3D scanning process, such as using chalk dust on reflective surfaces

Appreciation for the hard work and dedication put into the builds

Some viewers suggest starting next year's SEMA build earlier to reduce stress

Positive comments on the design and engineering of the project

Requests for wider angle shots to see the whole build process

Compliments on the finished product seen in person

Mixed opinions on the final look of the car and the headlights

Some viewers inspired to try 3D printing and scanning themselves

Overall admiration for the effort and outcome of the project

Related Articles

Solar Paneling for Camper Trucks: Health Update and Innovative Testing

B is for Build explores solar paneling for camper trucks in hot conditions. Updates on the host's health journey post-cancer diagnosis. Testing Ankor's panels and discussing treatment options. Embracing positivity amidst challenges.

B is for Build Founder's Cancer Battle: Treatment Plan and Reflection

B is for Build founder reveals cancer spread to lymph nodes after melanoma battle. Discusses treatment plan, challenges, and importance of positive outlook. Financial strain addressed. Emotional reflection on channel's impact.

Masterful Automotive Transformation: BRZ Build by B is for Build

Follow the B is for Build team as they transform a crashed BRZ into a masterpiece, tackling challenges like creating hood scoops and seamless body kit transitions, showcasing innovation and resilience in automotive customization.

B is for Build: BRZ Challenges and Insights in Car Building

B is for Build tackles challenges with the BRZ, from quarter panel welding to body kit adjustments. The team shares insights on pet nutrition and TV car show production practices, emphasizing perseverance in car building.