Mastering Tube Bending: Crafting a Unique F40 Chassis with Precision

- Authors

- Published on

- Published on

- Name

- By Dushyant

- (@dishs)

In this thrilling episode of StanceWorks, the team embarks on the challenging task of bending tubes for the iconic F40 chassis. Armed with meticulous measurements, cutting-edge 3D scanning technology, and a revamped set of tools, they strive to achieve the perfect fit for the main hoop. The goal? To craft a one-of-a-kind tube chassis using original Ferrari Bodywork, with a bold vision of surpassing the 1980s design standards. As they delve into the intricate process of aligning the chassis within the bodywork and table, unexpected discrepancies emerge, demanding a keen eye for detail and a touch of ingenuity.

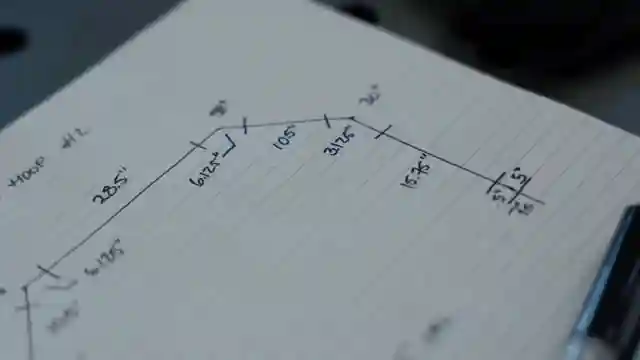

With the aid of a cutting-edge 3D scanner and precise CAD manipulation, the team delves deep into the heart of the alignment issue, meticulously analyzing the differences between the car's sides. Through multiple rounds of rescanning, realigning, and fine-tuning, they inch closer to the elusive perfection they seek. The focus then shifts to the tube bending process, as the team dusts off the trusty tubing bender and gears up for a detailed explanation of its inner workings. From cleaning and calibrating the equipment to executing a crucial calibration bend, every step is crucial in ensuring the accuracy of the tube structures that will shape the F40 chassis.

As the bending process unfolds, StanceWorks dives into the intricacies of using a Bend protractor, a tool essential for precision tube bending. Through a methodical approach of marking, measuring, and bending the tubes, they demonstrate their commitment to achieving flawless results. Despite minor setbacks and imperfections along the way, the team's dedication to excellence shines through as they meticulously plan adjustments to enhance the fit and aesthetics of the main hoop. With each bend and measurement, they edge closer to their ultimate goal of creating a tube chassis masterpiece that defies convention and sets a new standard in automotive craftsmanship.

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Watch F40 EVO // Improving the chassis and roll cage of an ICON! on Youtube

Viewer Reactions for F40 EVO // Improving the chassis and roll cage of an ICON!

Viewers appreciate the meticulous approach to building and attention to detail in the project

Some viewers find the channel underrated and express excitement for the custom frame F40 build

Positive comments on the craftsmanship, storyline, and videography of the channel

Suggestions for using tools like a bend protractor and digital magnetic protractor for accuracy in tube bending

Comments on the quality of merchandise related to the project

Some viewers mention the length of the video but appreciate the detailed explanations provided

Encouragement for the creator to continue ignoring negative comments and focusing on the project

Suggestions for unique YouTube merchandise ideas related to the build

Appreciation for the craftsmanship and dedication to perfection in the project

Some viewers express curiosity about specific details and aspects of the build

Related Articles

Building Custom Engine Run Stand for Ferrari F-140GA V12

StanceWorks builds a custom engine run stand for the powerful F-140GA V12 from a Ferrari 812 Superfast. Precision welding, quality materials, and collaboration with Send Cut Send ensure a durable and functional design.

Exploring CNC Machining with Carva: Precision Part Production Journey

StanceWorks introduces CNC machining with the Carva desktop machine, showcasing its features and capabilities. Follow their journey into precision part production and the excitement of creating custom components for their projects.

StanceWorks F40 Project: A-Pillar Crafting and Windshield 3D Scan

StanceWorks F40 project ramps up with technical details and body alignment focus. A-pillars crafted, fiberglass placeholders installed, and 3D scan planned for Lexan windshield replication. Support the project through subscriptions, merchandise, or Patreon.

StanceWorks Transforms E36 M3 and 328 with Custom Wheels and Enzitech Wrap

StanceWorks transforms neglected E36 M3 and E36 328 into stunning rides with custom AC Schnitzer and BBS LMS wheels. Full wrap in Enzitech's midnight purple elevates the E36's aesthetics. Experience the meticulous craftsmanship and passion of the team.