Engine Transformation: Optimizing Airflow for Peak Performance

- Authors

- Published on

- Published on

- Name

- By Dushyant

- (@dishs)

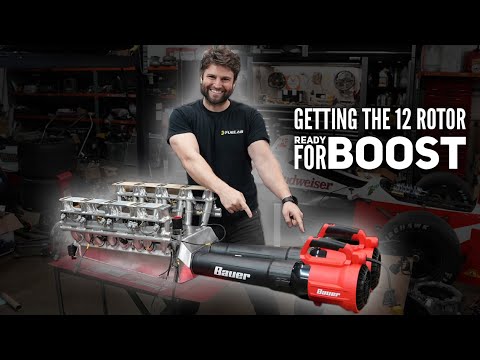

In this thrilling episode of Rob Dahm's automotive escapades, the team embarks on a mission to transform an engine into a powerhouse fit for a special project. With a keen eye for detail, they crank up the pressure to over 35 PSI, unveiling leaks through a dramatic display of smoke. The intake manifold undergoes a meticulous flattening process using a unique fly cutter, showcasing the team's dedication to perfection. As they tackle challenges head-on, a stone is skillfully employed to further refine the manifold, ensuring top-notch performance.

Amidst the chaos, a revelation strikes as the intake manifold is deemed beyond repair, prompting innovative solutions from the team. Enter a mass airflow sensor on a stick, a clever tool used to test airflow consistency with precision. The introduction of leaf blowers adds a competitive edge, as the team engages in a spirited contest to determine the most efficient airflow mover. Welding modifications to the manifold bring about significant changes, setting the stage for a dynamic airflow testing session.

With a blend of ingenuity and expertise, the team delves into the intricacies of airflow dynamics, uncovering discrepancies in the intake runners. Through meticulous adjustments and welding wizardry, the airflow is fine-tuned to perfection, paving the way for a promising dyno test. As the dust settles, the team stands proud, knowing that their efforts have elevated the intake manifold to a new level of performance. The stage is set for the ultimate test on the dyno, where the true capabilities of their creation will be put to the test.

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Watch $70 Leaf Blowers Saved the 12 Rotor From Dyno Disaster on Youtube

Viewer Reactions for $70 Leaf Blowers Saved the 12 Rotor From Dyno Disaster

Rob's hair blowing in the wind is a topic of amusement among viewers

Concerns and suggestions regarding the machining techniques used by Rob

Discussion on the design and functionality of the 12-rotor engine's intake manifold

Suggestions to consider boost pressure and throttle blade placement for improved performance

Excitement for seeing the engine on the dyno and in a vehicle

Critiques on the flow testing methods used and the need for further testing with throttle bodies

Comments on the potential impact of turbocharging on the manifold's performance

Appreciation for Rob's unique approach and personality

Recommendations for using proper tools and techniques in machining

Speculation on the racecar seen in the background of the video

Related Articles

Rob Dahm: Shiny 3D Scanner, Clutch Kit, and 3D Printed Car Ducts

Rob Dahm showcases the Shiny 3D scanner's advanced capabilities, discusses a new clutch kit, and introduces Eight Sleep's innovative technology. The team delves into 3D printing ducts for the car, highlighting challenges and successes in the process.

Rob Dahm's Team Revs Up Three-Rotor Engine for Pikes Peak Success

Rob Dahm's team prepares the three-rotor engine for Pikes Peak, overcoming challenges like rotor damage and seal issues. With meticulous rebuilding and innovative techniques, they enhance performance for the upcoming race.

Building the Lightest Mazda Rotary Engine: Precision and Billet Components

Rob Dahm's team works on creating the lightest Mazda-based rotary engine ever, focusing on billet components and precision assembly for optimal performance.

Reviving an Iconic Indie Car: Unveiling the Transmission Casing

Rob Dahm revives an iconic Indie Car, unveiling its versatile transmission casing. Discover the car's history, intricate mechanics, and the team's journey to restore it to its former racing glory.