Engine Oil Pressure Issues: Resolved and Celebrated | Rob Dahm

- Authors

- Published on

- Published on

- Name

- By Dushyant

- (@dishs)

In this latest installment from the Rob Dahm channel, the intrepid team embarks on a quest to uncover the root cause of their engine's oil pressure woes. Brace yourself for a rollercoaster ride of automotive drama as they delve into the heart of the issue. With bated breath, they examine the stock oil pan, which has been plagued by subtle drops in oil pressure. Alas, the front bearing has taken a hit, leading to low oil pressure, but fear not, for the oil is flowing ever so gracefully, providing a cooling respite for the beleaguered motor.

But wait, there's more! The team decides to seize this opportunity to not only replace the bearings but also install the correct transmission, ensuring optimum performance for their trusty steed. As they dive deeper into the car's inner workings, they stumble upon a shocking revelation - the fuel lines are cracked! It's a miracle they've held up this long, considering the rigors of ethanol usage. A stern reminder to always be vigilant with your fuel system, folks!

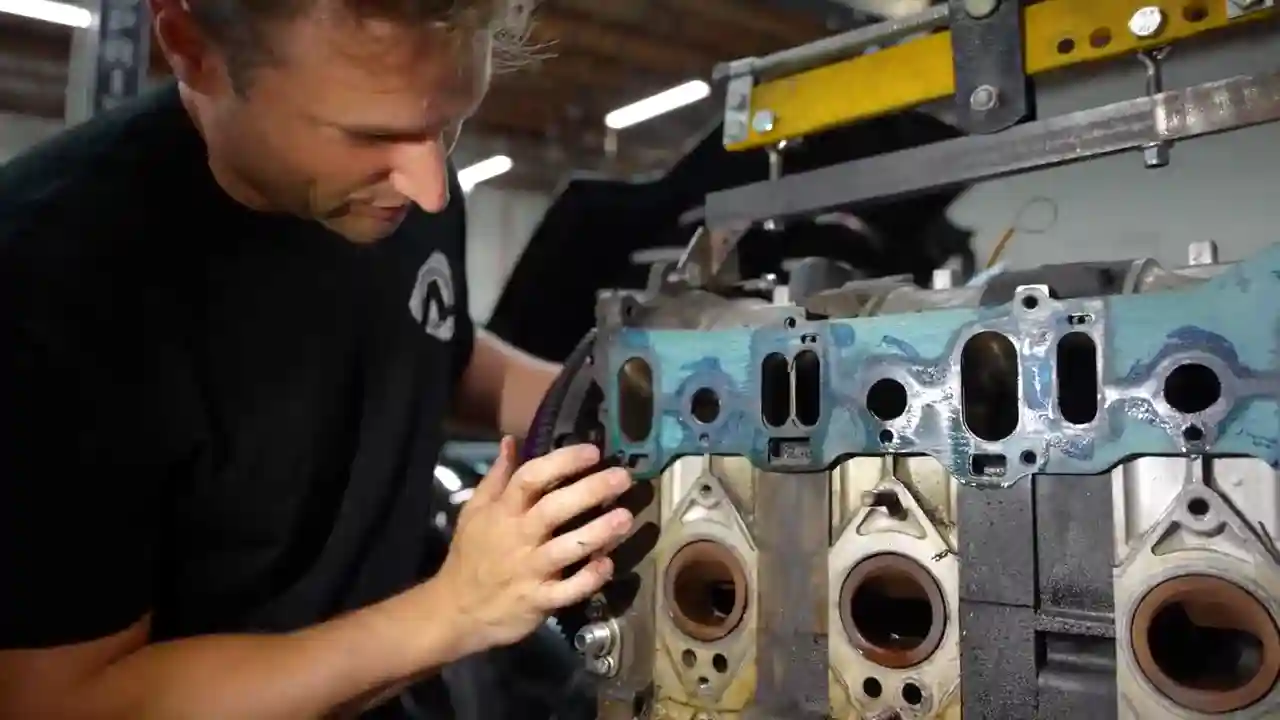

Undeterred by these setbacks, our intrepid heroes soldier on, undeterred by the prospect of burning their beloved car to the ground. The transmission is deftly removed, revealing an engine mount that has seen better days. And lo and behold, upon removing the oil pan, they discover... nothing! No bearings in sight. However, the front cover is still taken off to inspect the front bearing, which shows signs of wear and copper exposure. But fear not, for salvation is at hand! A ball bearing front piece from EJ is procured, ensuring the engine can withstand the rigors of their relentless driving escapades.

In a twist of fate, it is revealed that the oil pressure regulator was the culprit all along! Vibrations caused it to back out, leading to the oil pressure woes. But let's not lay blame on Racing Beat, for their product is not at fault. It's simply a case of "this can happen" in the world of high-performance driving. With the issue resolved, the team breathes a collective sigh of relief, celebrating the fact that the engine remains intact, sparing them the arduous task of tearing it apart. And so, they bid adieu to their mechanical misadventures, reveling in the triumph of their perseverance.

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Watch I thought Rotaries were supposed to be fragile?! The 3 Rotor won’t die on Youtube

Viewer Reactions for I thought Rotaries were supposed to be fragile?! The 3 Rotor won’t die

Rob's engines becoming too reliable

Welding the oil pressure regulator nut

Mechanic skill issues with rotary engines

Appreciation for DIY work on the channel

Surprise at the shorter video length

Positive feedback on the video's content

Excitement for future content

Red Loctite and tack welds for the regulator

Safety wiring or bend tab washer suggestions

Interest in running engines on Penzoil

Mention of Mazzei's 5 rotor engine

Flow vs pressure discussion

Request for Liquid Piston engine video

Personal experiences with oil regulator failure

Appreciation for learning from the channel

Humorous comment about service life

Safety wire suggestion for the regulator

Interest in E&J bearing installation video

Mixed opinions on rotary engine reliability

Mid-engine swap and rotary engine thoughts

Suggestion to wire lock the oil pressure cap

Curiosity about different width center irons

Related Articles

Rob Dahm: Shiny 3D Scanner, Clutch Kit, and 3D Printed Car Ducts

Rob Dahm showcases the Shiny 3D scanner's advanced capabilities, discusses a new clutch kit, and introduces Eight Sleep's innovative technology. The team delves into 3D printing ducts for the car, highlighting challenges and successes in the process.

Rob Dahm's Team Revs Up Three-Rotor Engine for Pikes Peak Success

Rob Dahm's team prepares the three-rotor engine for Pikes Peak, overcoming challenges like rotor damage and seal issues. With meticulous rebuilding and innovative techniques, they enhance performance for the upcoming race.

Building the Lightest Mazda Rotary Engine: Precision and Billet Components

Rob Dahm's team works on creating the lightest Mazda-based rotary engine ever, focusing on billet components and precision assembly for optimal performance.

Reviving an Iconic Indie Car: Unveiling the Transmission Casing

Rob Dahm revives an iconic Indie Car, unveiling its versatile transmission casing. Discover the car's history, intricate mechanics, and the team's journey to restore it to its former racing glory.