Building Custom Tube Chassis for Unique F40 Variant: Precision Craftsmanship

- Authors

- Published on

- Published on

- Name

- By Dushyant

- (@dishs)

Today on StanceWorks, the team embarks on an epic journey to build a custom tube chassis for an F40 like no other. With all the necessary materials in hand, they dive headfirst into the meticulous process of crafting a chassis from scratch. This isn't just any F40; it's destined to become an F40 Evo or F40 XX, pushing the boundaries of what's possible. Utilizing measurements from Nigel Mansell's F40, they meticulously set up the Bodywork on the chassis table, laying the foundation for what's to come.

Precision is key as they use parts from Senot to locate the bodywork and tube work with utmost accuracy. Welding becomes a crucial skill as they assemble tube stands designed for strength and functionality. The team's attention to detail shines through as they ensure the rocker panels are centered, tapered correctly, and securely clamped in place using innovative can't twist clamps. Every measurement is scrutinized multiple times to guarantee symmetry and alignment, setting the stage for a flawless build.

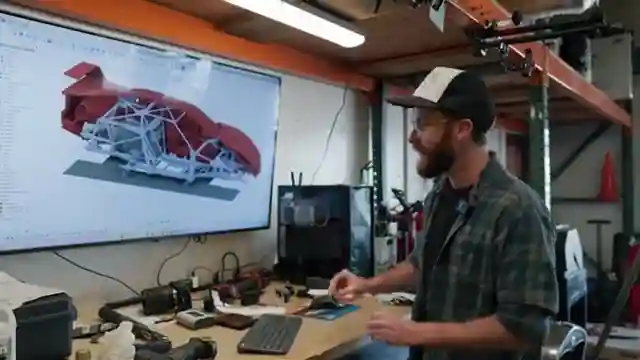

In a stroke of genius, they turn to a CAD model of an original F40 chassis for reference, allowing them to plan the build with unparalleled accuracy. By combining 3D models and scans, they visualize how all components will come together, ensuring a perfect fit. This CAD model serves as a guiding light, steering them towards building a chassis that not only meets but exceeds expectations. The team's passion and dedication shine through as they push the boundaries of automotive craftsmanship, creating a masterpiece in the making.

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Watch F40 EVO // Hand-building a chassis for my V12-powered LEGEND! (4K) on Youtube

Viewer Reactions for F40 EVO // Hand-building a chassis for my V12-powered LEGEND! (4K)

Many Bothans died to bring the CAD model of an original F40

Excitement for the upcoming project and the attention to detail

Appreciation for the craftsmanship and dedication to perfection

Recognition of the quality and content of the channel

Anticipation for the completion of the F40 build

Comments on the complexity and detail of the project

Interest in the tools and techniques used in the build

Excitement for the progress and development of the project

Encouragement to continue sharing the journey and details

Comparison of the project to childhood dreams and admiration for the talent involved

Related Articles

Building Custom Engine Run Stand for Ferrari F-140GA V12

StanceWorks builds a custom engine run stand for the powerful F-140GA V12 from a Ferrari 812 Superfast. Precision welding, quality materials, and collaboration with Send Cut Send ensure a durable and functional design.

Exploring CNC Machining with Carva: Precision Part Production Journey

StanceWorks introduces CNC machining with the Carva desktop machine, showcasing its features and capabilities. Follow their journey into precision part production and the excitement of creating custom components for their projects.

StanceWorks F40 Project: A-Pillar Crafting and Windshield 3D Scan

StanceWorks F40 project ramps up with technical details and body alignment focus. A-pillars crafted, fiberglass placeholders installed, and 3D scan planned for Lexan windshield replication. Support the project through subscriptions, merchandise, or Patreon.

StanceWorks Transforms E36 M3 and 328 with Custom Wheels and Enzitech Wrap

StanceWorks transforms neglected E36 M3 and E36 328 into stunning rides with custom AC Schnitzer and BBS LMS wheels. Full wrap in Enzitech's midnight purple elevates the E36's aesthetics. Experience the meticulous craftsmanship and passion of the team.