Building a Four-Rotor Engine: Converting Two Two-Rotor Engines into Powerhouse Performance

- Authors

- Published on

- Published on

- Name

- By Dushyant

- (@dishs)

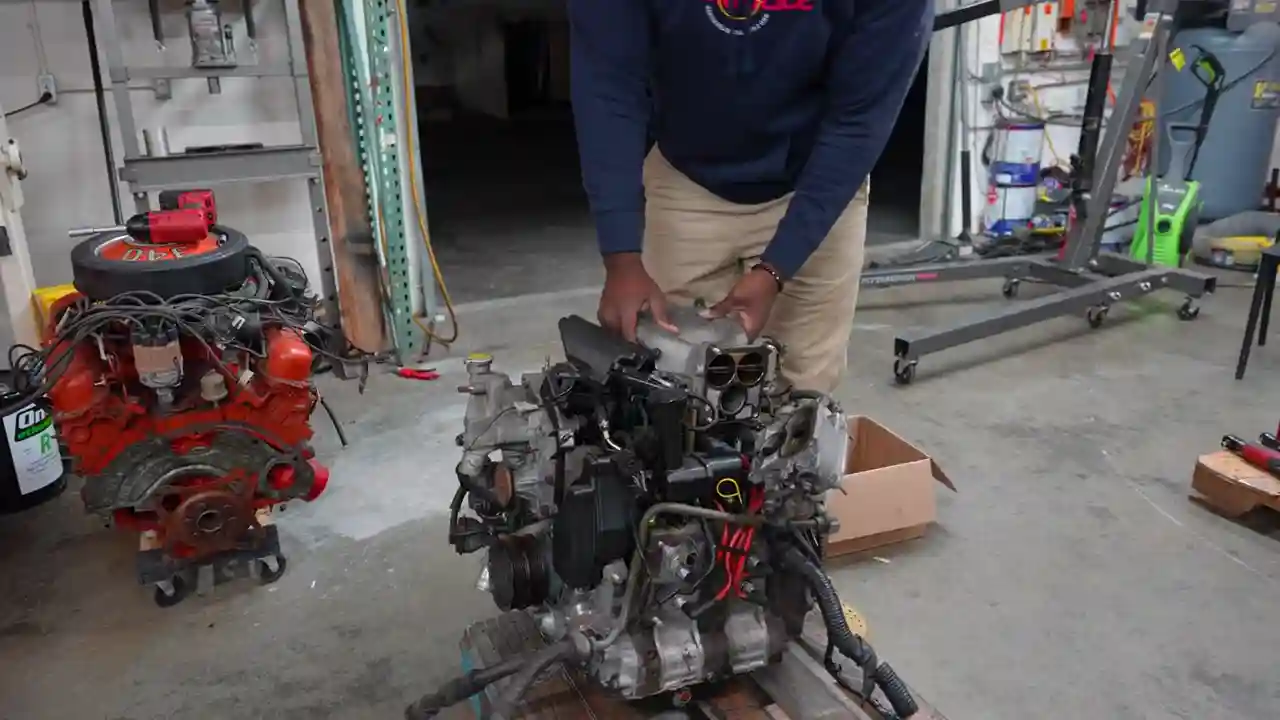

In this riveting installment from the channel Rob Dahm, the team embarks on a daring quest to build a four-rotor engine using parts from two two-rotor engines. A seemingly straightforward task, but as they soon discover, it's not as easy as it sounds. Armed with a list of required components, they turn to the experts at JDM California to make their lives a little easier by acquiring two motors. Little did they know that the process would be a steep learning curve.

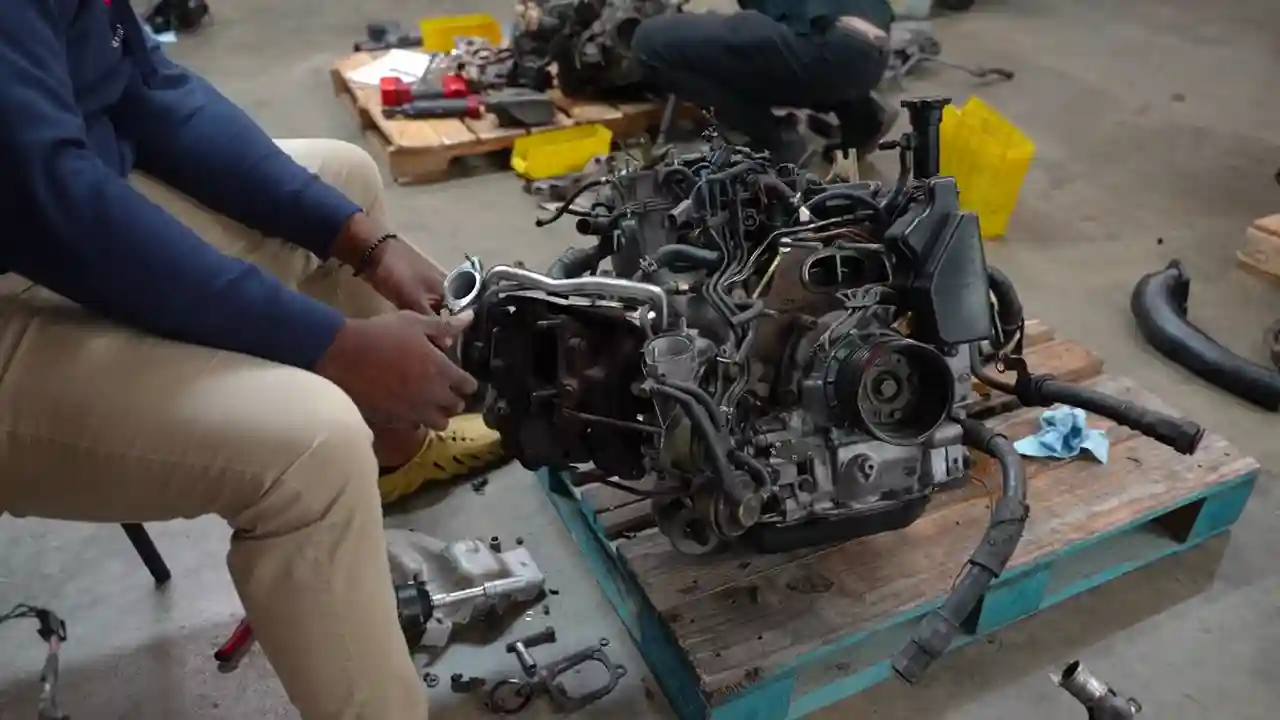

The key to transforming a two-rotor engine into a four-rotor beast lies in the E shaft and the long bolts that hold the engine together. But that's not all. Four-rotor engines have a different arrangement of bearings, with special irons that flip the way the bearings are positioned. It's a delicate dance of outer bearings, inner bearings, and a dummy plate in the middle. These three crucial pieces are specific to four-rotor engines and not found in their two-rotor counterparts.

But the challenges don't end there. The team soon realizes that the biggest hurdle with four-rotor engines lies in getting air into the ports. With big ports and small ports to contend with, they must strike a balance between using more parts for a full peripheral engine or sticking with the stock four-rotor setup for greater control. It's a decision that will shape the performance and character of their creation.

As they delve deeper into the project, the team contemplates the engine's ability to withstand the rigors of drifting. The intense heat and power that the engine will experience require a heavy focus on cooling and flow. It's a matter of keeping the engine alive under the most demanding conditions. The team acquires three two-rotor engines, each with its own story. They engage in a friendly competition, assessing the value and condition of the parts salvaged from each engine.

With the engines disassembled, the team faces a mix of triumphs and setbacks. One engine proves to be in rough shape, with bent parts and snapped covers. But amidst the chaos, they find hope. There are usable parts, rotors that show promise, and even a chance to repurpose a plate for another purpose. The team's determination and resilience shine through as they salvage what they can and push forward with their ambitious goal of building a powerful four-rotor engine.

In the end, it's not just about the destination but the journey itself. The team's passion for cars and their shared love for the process of building something extraordinary is palpable. They may face challenges and setbacks, but their unwavering dedication and unyielding spirit keep them going. With a glimmer of success on the horizon, the team is poised to create a four-rotor engine that will leave enthusiasts in awe.

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Watch Can you build a 4 ROTOR from USED RX-7 Engines?? on Youtube

Viewer Reactions for Can you build a 4 ROTOR from USED RX-7 Engines??

Appreciation for transparency on pricing and parts needed

Excitement for the collaboration between Rob and Hert

Anticipation for the rebuild and enjoyment of watching Hert work on his own car

Interest in seeing expensive parts being cleaned

Enthusiasm for learning about rotaries and building their own engines

Appreciation for the balance of tech knowledge and humor in the video

Compliments to Rob for being friendly and knowledgeable

Excitement for the collaboration between two favorite YouTubers

Hope for more collaborations and spreading of rotary love

Excitement for the upcoming series and project

Appreciation for Hert's presence in the videos

Anticipation for the outcome of the project and the "franken rotor"

Observations of Hert dropping his wallet and a running rotary in the background

Requests for parts and enthusiasm for the crossover episode

Knowledge and advice on building a 4-rotor engine

Jokes about Hert's car skills and Rob not being in Hert's music video

Personal experiences and mishaps with engine building and torqueing parts

Related Articles

Rob Dahm: Shiny 3D Scanner, Clutch Kit, and 3D Printed Car Ducts

Rob Dahm showcases the Shiny 3D scanner's advanced capabilities, discusses a new clutch kit, and introduces Eight Sleep's innovative technology. The team delves into 3D printing ducts for the car, highlighting challenges and successes in the process.

Rob Dahm's Team Revs Up Three-Rotor Engine for Pikes Peak Success

Rob Dahm's team prepares the three-rotor engine for Pikes Peak, overcoming challenges like rotor damage and seal issues. With meticulous rebuilding and innovative techniques, they enhance performance for the upcoming race.

Building the Lightest Mazda Rotary Engine: Precision and Billet Components

Rob Dahm's team works on creating the lightest Mazda-based rotary engine ever, focusing on billet components and precision assembly for optimal performance.

Reviving an Iconic Indie Car: Unveiling the Transmission Casing

Rob Dahm revives an iconic Indie Car, unveiling its versatile transmission casing. Discover the car's history, intricate mechanics, and the team's journey to restore it to its former racing glory.